Large Restaurant Stock Pots

- Product Information

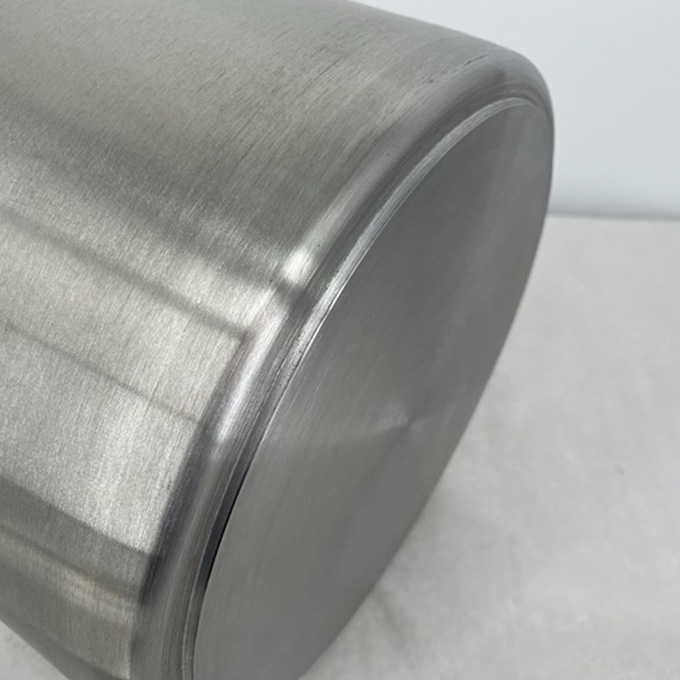

Restaurant Stock Pots are designed specifically for restaurant kitchens and other settings. They feature a silvery-white metallic sheen and a cylindrical body with a round lid and handles. They also feature two semicircular handles on either side. These pots are typically made of stainless steel, offering excellent heat resistance and durability. They can be used for simmering broth, making sauces, and preparing other large quantities of food. For restaurants, these pots are ideal for cooking large quantities of ingredients and are quick and easy to use, enabling efficient operation and management by kitchen staff.

Restaurant Stock Pots Parameters:

| CODE 05 STYLE | Dimension | VOLUME | BODY & LID THICK(mm) | ALUMINUM THICK(mm) |

| SP302005 | Ф300*H200 | 14L | 0.8 | 4 |

| SP322205 | Ф320*H220 | 17L | 0.8 | 4 |

| SP362405 | Ф360*H240 | 23L | 1 | 4 |

| SP402605 | Ф400*H260 | 32L | 1 | 4 |

| SP452805 | Ф450*H280 | 44L | 1 | 4 |

| SP503005 | Ф500*H300 | 58L | 1 | 4 |

| SP553505 | Ф550*H350 | 83L | 1 | 4 |

| SP604005 | Ф600*H400 | 113L | 1 | 5 |

Restaurant Stock Pots Feature:

1. High-Quality Materials

Restaurant stock pots are typically constructed from high-quality stainless steel. This stainless steel offers excellent corrosion resistance, making it resistant to the erosion of various ingredients and seasonings during prolonged cooking. Its corrosion resistance has been proven through a professional salt spray test lasting up to 72 hours, with no visible surface rust, ensuring the pot's longevity and food safety.

2. Triple-Layer Composite Bottom

The pot's bottom features a three-layer composite structure. The middle layer is aluminum, up to 4-5 mm thick, and the sides are stainless steel. This design allows for rapid and even heat transfer, increasing thermal efficiency by approximately 30%-40%. Compared to conventional single-layer pots, the triple-layer composite bottom effectively reduces temperature unevenness during cooking, ensuring more even heating of ingredients, preventing burnt areas and uneven cooking.

3. Excellent High-Temperature Resistance

This pot offers excellent high-temperature resistance, ensuring stability under prolonged high-temperature cooking conditions. After testing, it has been shown to withstand continuous use for hours at temperatures around 300°C without material deformation or performance degradation. This allows it to meet the diverse high-temperature cooking needs of restaurant kitchens, such as boiling, stewing, and simmering, ensuring cooking results and efficiency.

4. Diverse Capacity Specifications

Restaurant Stock Pots offer a variety of capacity specifications to meet the needs of restaurants of varying sizes. Common capacity specifications include 14L, 17L, 23L, 32L, 44L, 58L, 83L, and 113L, corresponding to pot dimensions (diameter × height) of 300 × H200, 320 × H220, 360 × H240, 400 × H260, 450 × H280, 500 × H300, 550 × H350, and 600 × H400, respectively. Users can choose the appropriate capacity based on their restaurant's cooking needs and kitchen space, offering convenience and flexibility.

5. Moderate Thickness

The pot body (including the pot body and lid) is generally between 0.8 and 1 mm thick, with the aluminum layer on the bottom being 4 to 5 mm thick. This thickness ensures the pot's durability without being excessively bulky. Actual measurements and user tests have shown that pots of this thickness can withstand significant pressure and weight during cooking, remain resilient to deformation, and are easy to carry and operate.

6. Lid Handle

The pot lid is equipped with a convenient and practical handle. Made of high-temperature-resistant material, the handle remains stable during high-temperature cooking and will not damage or deform due to prolonged exposure to high temperatures. Tests have shown that the handle can withstand several hours of normal use at 150°C, allowing chefs to open and close the lid for seasoning, stirring, and other tasks during cooking, improving cooking convenience and efficiency.

Restaurant Stock Pots Application:

1. High-end Restaurant Kitchens

In high-end restaurant kitchens, restaurant stock pots are indispensable cooking tools. They can be used to simmer a variety of broths, such as beef broth and chicken broth. Their three-layer composite bottom design and excellent high-temperature resistance ensure even heating during the long simmering process, preserving the original flavor of the ingredients. Furthermore, their various capacity sizes meet the cooking needs of different dishes.

2. Fast Food Chain Kitchens

In fast food chain kitchens, restaurant stock pots are used to quickly prepare large quantities of soup bases or sauces. Fast food restaurants often need to serve large quantities of food in a short period of time, and the pot's large capacity and efficient heat conduction meet this demand. For example, a chain restaurant that sells 500-800 bowls of fast food daily can prepare a sufficient amount of soup base in a single batch using a 113L restaurant stock pot, reducing the time and labor costs of frequent simmering, increasing service time, and ensuring the taste and quality of the fast food.

3. Hotel Chinese Restaurant Kitchens

In hotel Chinese restaurant kitchens, Restaurant Stock Pots can be used to cook a variety of Chinese dishes. Chinese cooking often requires extensive stewing, boiling, and braising, and the pot's high-temperature resistance and large capacity meet these needs. For example, when a hotel hosts a large banquet, large quantities of dishes such as braised pork and chicken soup need to be prepared. Using Restaurant Stock Pots allows a sufficient number of dishes to be cooked at once, maintaining a consistent temperature and texture, thus improving the hotel's Chinese restaurant's culinary capabilities and banquet service quality.

4. Western Restaurant Kitchens

In Western restaurant kitchens, Restaurant Stock Pots are primarily used to prepare various Western soups and sauces. Western soups such as cream of mushroom soup and tomato soup require specific temperatures and cooking times. The pot's three-layer composite bottom ensures even heat distribution, resulting in a more delicate and refined soup texture. For example, a medium-sized Western restaurant might prepare 30-50 servings of soup daily. Using Restaurant Stock Pots with a capacity of 23L-32L allows for flexible adjustments in cooking volume based on order volume, ensuring quality while avoiding waste and improving the restaurant's profitability.

5. Hot Pot Restaurant Kitchen

In hot pot restaurant kitchens, Restaurant Stock Pots are used to prepare hot pot base. Hot pot base requires high temperatures and a long simmering time to fully release the flavors of the spices and ingredients. The pot's high-temperature resistance and large capacity make it highly suitable for this task. Restaurant Stock Pots can produce a sufficient amount of hot pot base in one go, ensuring every table of guests enjoys a rich, flavorful hot pot cooked to the perfect temperature, improving customer satisfaction and operational efficiency.

Restaurant Stock Pots Maintenance:

1. Clean promptly after use

Restaurant Stock Pots should be cleaned promptly after use. First, soak the pot in warm water (between 30°C and 40°C) for 10-15 minutes to soften any food residue. Then, use a soft-bristled brush or sponge with a neutral detergent (such as dish soap with a pH of 7-8) to gently scrub the inside and outside of the pot. Pay special attention to the joint between the bottom and lid, as well as the handles, as these areas are prone to dirt buildup. Finally, rinse thoroughly with clean water to ensure no detergent residue remains, which can affect the taste and food safety of your next meal.

2. Avoid Dry-Boiling

During use, avoid allowing the pot to dry-boil. Dry-boiling can cause the pot to heat up rapidly, damage the material, and even pose a fire hazard. Cooks should always monitor the ingredients and liquid levels in the pot to ensure sufficient liquid is always present. If the liquid boils away, turn off the heat immediately and wait for the pot to cool slightly before handling it. Generally, when the liquid in the pot is reduced to 1/3 of its capacity, add an appropriate amount of liquid to prevent it from drying out.

3. Protect from moisture during storage

Restaurant Stock Pots should be stored away from moisture. While stainless steel is corrosion-resistant, it can still rust if stored in a humid environment for extended periods. Therefore, store pots in a dry, ventilated kitchen cabinet, away from water sources or damp walls. Before storing, ensure the pot is completely dry. Wipe the inside and outside of the pot with a dry cloth and place a dry paper towel between the pot and the lid to absorb any remaining moisture. It is recommended to remove the pot every month and inspect it for rust or other damage. Any issues should be addressed promptly.

4. Regularly inspect the exterior of the pot

Regularly inspecting the exterior of the pot is an important part of pot maintenance. During this inspection, carefully inspect the pot for scratches, dents, or other signs of damage. Shallow scratches (less than 0.5mm) can be repaired using a specialized metal polish. Apply the polish evenly to the scratched area, then gently rub with a soft cloth in circular motions. Rinse thoroughly with water and dry thoroughly. For dents or other more severe damage, assess the impact on cooking performance. If necessary, contact a professional repair technician for repair or replacement to ensure cooking quality and safety.

Restaurant Stock Pots FAQ:

Why does food stick to Restaurant Stock Pots?

Food can stick to stainless steel pots if the pot isn't preheated or the oil isn't hot enough. To prevent sticking, preheat the pot properly and add oil before introducing your ingredients. This creates a non-stick effect, allowing for easy cooking and cleanup.

How to maintain a Restaurant Stock Pot?

Maintaining a stainless steel soup pot involves regular cleaning with warm soapy water and avoiding harsh abrasives. For stubborn stains, use a baking soda paste or a stainless steel cleaner. Proper care ensures the pot remains shiny and functional for years.

What are the advantages of a stainless steel lid?

A stainless steel lid is durable and helps retain heat and moisture within the pot, enhancing the cooking process. It also matches the pot’s aesthetic, creating a cohesive look in your kitchen, and is easy to clean, contributing to the overall convenience of using the pot.