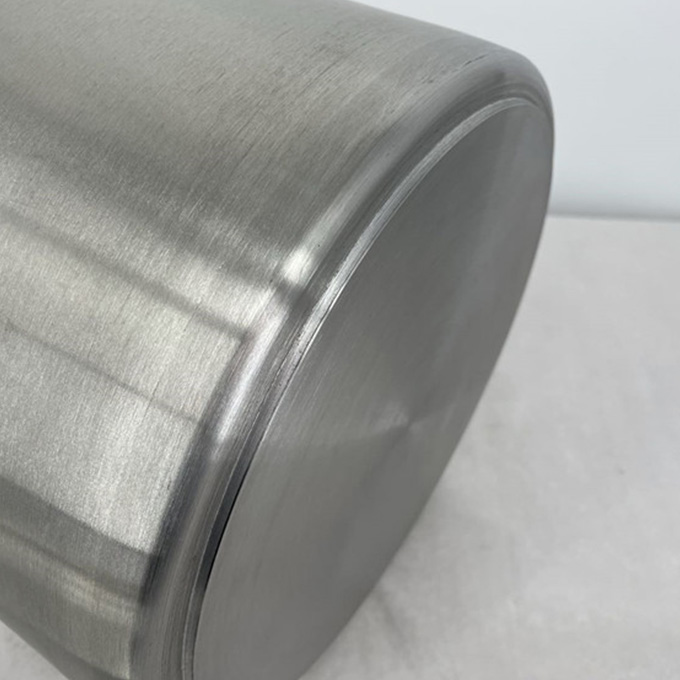

Heavy Bottom Stainless Steel Stock Pot

- Product Information

Heavy Bottom Stainless Steel Stock Pot is a high-end kitchen appliance designed for efficient cooking and durability. It is made of 304 stainless steel, which has excellent corrosion resistance and anti-oxidation properties. The bottom of the stock pot is thickened, usually between 4-5mm, to ensure uniform heat distribution and fast heat conductivity. The stock pot offers a variety of capacity options from 14L to 113L to meet the needs of different scenarios such as home, restaurant, hotel, etc. It is equipped with two side stainless steel handles and a top handle to ensure convenience and safety during transportation and operation. It can be used to cook soup, stew meat, cook pasta, and even cook large quantities, such as preparing food for family gatherings or restaurants.

Heavy Bottom Stainless Steel Stock Pot Parameters:

| CODE 03 STYLE | Dimension | VOLUME | BODY & LID THICK(mm) | ALUMINUM THICK(mm) |

| SP302003 | Ф300*H200 | 14L | 0.8 | 4 |

| SP322203 | Ф320*H220 | 17L | 0.8 | 4 |

| SP362403 | Ф360*H240 | 23L | 1 | 4 |

| SP402603 | Ф400*H260 | 32L | 1 | 4 |

| SP452803 | Ф450*H280 | 44L | 1 | 4 |

| SP503003 | Ф500*H300 | 58L | 1 | 4 |

| SP553503 | Ф550*H350 | 83L | 1 | 4 |

| SP604003 | Ф600*H400 | 113L | 1 | 5 |

Heavy Bottom Stainless Steel Stock Pot Features:

1. Home kitchen

In the home kitchen, the Heavy Bottom Stainless Steel Stock Pot is a great helper for cooking traditional food and hosting family dinners. Take cooking Cantonese-style cured meat clay pot rice as an example. Using a 17L stock pot with a diameter of 320mm and a height of 220mm, you can cook 4-6 servings of clay pot rice at the same time. Soak the sausage, cured meat and other ingredients in advance, put them into the pot together with the rice, and add an appropriate amount of water. The sealing performance of the stock pot ensures that the water will not evaporate excessively during the cooking process, and the rice fully absorbs the aroma of the cured meat. The rice grains are distinct, and a layer of golden and crispy rice crust forms at the bottom, adding deliciousness to family dinners. This efficient cooking ability makes home cooking easier and more enjoyable.

2. Restaurant kitchen

In the restaurant kitchen, the stock pot is a key tool for efficient food delivery. Take a Chinese restaurant that receives 200-300 guests a day as an example. The kitchen uses a 50L stock pot with a diameter of 400mm and a height of 400mm to make the signature pickled fish. Before the meal every day, the chef prepares the fish fillets, pickled cabbage and other ingredients according to the portion and puts them into the stock pot. The uniform heat conductivity of the stock pot ensures that each portion of pickled fish is quickly cooked within 3-5 minutes, the fish is tender and the soup is sour and refreshing. Even during peak hours, it can ensure that every table of guests can enjoy the steaming hot and consistent quality dishes in time. This efficient cooking performance significantly improves the restaurant's operating efficiency and customer satisfaction.

3. Hotel kitchen

Hotel kitchens need to cope with the needs of various large banquets and buffets, and Heavy Bottom Stainless Steel Stock Pot plays an important role in this. Take a five-star hotel that hosts a wedding banquet for 500 people as an example. The chef team uses a 58L stock pot with a diameter of 500mm and a height of 300mm to cook Buddha Jumps Over the Wall at the wedding banquet. Abalone, sea cucumber, fish maw and other high-end ingredients are processed and stewed separately in advance, and then put into the soup pot according to the proportion. The durability and large capacity of the soup pot can accommodate all ingredients and broth. After 4-6 hours of slow stewing, the Buddha Jumps Over the Wall soup is rich and mellow, and the ingredients are soft and tasty, bringing guests the ultimate taste enjoyment. This high-quality cooking effect has improved the hotel's catering service level and competitiveness.

4. Food processing plant

In the field of food processing, soup pots are used to make various pre-prepared foods. Take the factory that produces quick-frozen dumplings as an example. 500-1000kg of dumplings need to be processed every day. The factory uses an 83L soup pot with a diameter of 550mm and a height of 350mm for cooking. The precise size and large capacity of the soup pot enable it to cook 30-50kg of dumplings at a time. With the automated production line, dumplings are cooked, cooled and packaged within 8-10 minutes. The antioxidant properties of the soup pot ensure that the water quality is not polluted during the long and high-temperature cooking process, the dumpling skin remains chewy, and the filling is delicious and juicy. This efficient production capacity and stable quality assurance enable food processing plants to meet market demand and improve production efficiency and product quality.

5. Charity kitchens

Charity kitchens require a large amount of cooking equipment to prepare free meals. For example, a charity kitchen that provides meals for 200-300 poor people every day uses a 113L soup pot with a diameter of 600mm and a height of 400mm to make large pot dishes. The soup pot's stable structure and handle design make it easy for volunteers to carry and distribute food. Even in the case of limited resources, the soup pot's large capacity and efficient cooking performance can quickly provide recipients with hot and delicious meals, such as stewed potato beef soup and vegetable stew, to meet people's nutritional needs. This reliability and efficiency ensure that charities can continue to provide support to people in need.

6. Community center kitchens

Community center kitchens provide residents with a variety of cooking courses and activities. Taking the cooking training course as an example, the instructor used a 23L soup pot with a diameter of 360mm and a height of 240mm to demonstrate the traditional method of making beef stewed with radish. The uniform heating performance of the soup pot ensures that the beef is evenly heated during the stewing process and the radish is soft and tasty. By observing the instructor's operation, the trainees can intuitively learn skills such as heat control and ingredient matching. The durability and easy cleaning of the soup pot keep it in good condition during frequent teaching use, providing community residents with a high-quality cooking learning experience. This versatility and reliability enable the community center to better serve residents and promote the harmonious development of the community.

Heavy Bottom Stainless Steel Stock Pot Application:

1. Home kitchen

In the home kitchen, the Heavy Bottom Stainless Steel Stock Pot is a great helper for cooking traditional food and hosting family dinners. Take cooking Cantonese-style cured meat clay pot rice as an example. Using a 17L stock pot with a diameter of 320mm and a height of 220mm, you can cook 4-6 servings of clay pot rice at the same time. Soak the sausage, cured meat and other ingredients in advance, put them into the pot together with the rice, and add an appropriate amount of water. The sealing performance of the stock pot ensures that the water will not evaporate excessively during the cooking process, and the rice fully absorbs the aroma of the cured meat. The rice grains are distinct, and a layer of golden and crispy rice crust forms at the bottom, adding deliciousness to family dinners. This efficient cooking ability makes home cooking easier and more enjoyable.

2. Restaurant kitchen

In the restaurant kitchen, the stock pot is a key tool for efficient food delivery. Take a Chinese restaurant that receives 200-300 guests a day as an example. The kitchen uses a 50L stock pot with a diameter of 400mm and a height of 400mm to make the signature pickled fish. Before the meal every day, the chef prepares the fish fillets, pickled cabbage and other ingredients according to the portion and puts them into the stock pot. The uniform heat conductivity of the stock pot ensures that each portion of pickled fish is quickly cooked within 3-5 minutes, the fish is tender and the soup is sour and refreshing. Even during peak hours, it can ensure that every table of guests can enjoy the steaming hot and consistent quality dishes in time. This efficient cooking performance significantly improves the restaurant's operating efficiency and customer satisfaction.

3. Hotel kitchen

Hotel kitchens need to cope with the needs of various large banquets and buffets, and Heavy Bottom Stainless Steel Stock Pot plays an important role in this. Take a five-star hotel that hosts a wedding banquet for 500 people as an example. The chef team uses a 58L stock pot with a diameter of 500mm and a height of 300mm to cook Buddha Jumps Over the Wall at the wedding banquet. Abalone, sea cucumber, fish maw and other high-end ingredients are processed and stewed separately in advance, and then put into the soup pot according to the proportion. The durability and large capacity of the soup pot can accommodate all ingredients and broth. After 4-6 hours of slow stewing, the Buddha Jumps Over the Wall soup is rich and mellow, and the ingredients are soft and tasty, bringing guests the ultimate taste enjoyment. This high-quality cooking effect has improved the hotel's catering service level and competitiveness.

4. Food processing plant

In the field of food processing, soup pots are used to make various pre-prepared foods. Take the factory that produces quick-frozen dumplings as an example. 500-1000kg of dumplings need to be processed every day. The factory uses an 83L soup pot with a diameter of 550mm and a height of 350mm for cooking. The precise size and large capacity of the soup pot enable it to cook 30-50kg of dumplings at a time. With the automated production line, dumplings are cooked, cooled and packaged within 8-10 minutes. The antioxidant properties of the soup pot ensure that the water quality is not polluted during the long and high-temperature cooking process, the dumpling skin remains chewy, and the filling is delicious and juicy. This efficient production capacity and stable quality assurance enable food processing plants to meet market demand and improve production efficiency and product quality.

5. Charity kitchens

Charity kitchens require a large amount of cooking equipment to prepare free meals. For example, a charity kitchen that provides meals for 200-300 poor people every day uses a 113L soup pot with a diameter of 600mm and a height of 400mm to make large pot dishes. The soup pot's stable structure and handle design make it easy for volunteers to carry and distribute food. Even in the case of limited resources, the soup pot's large capacity and efficient cooking performance can quickly provide recipients with hot and delicious meals, such as stewed potato beef soup and vegetable stew, to meet people's nutritional needs. This reliability and efficiency ensure that charities can continue to provide support to people in need.

6. Community center kitchens

Community center kitchens provide residents with a variety of cooking courses and activities. Taking the cooking training course as an example, the instructor used a 23L soup pot with a diameter of 360mm and a height of 240mm to demonstrate the traditional method of making beef stewed with radish. The uniform heating performance of the soup pot ensures that the beef is evenly heated during the stewing process and the radish is soft and tasty. By observing the instructor's operation, the trainees can intuitively learn skills such as heat control and ingredient matching. The durability and easy cleaning of the soup pot keep it in good condition during frequent teaching use, providing community residents with a high-quality cooking learning experience. This versatility and reliability enable the community center to better serve residents and promote the harmonious development of the community.

Heavy Bottom Stainless Steel Stock Pot Maintenance:

1. Cleaning and Maintenance

After use, wait for the Heavy Bottom Stainless Steel Stock Pot to cool naturally to a warm state before cleaning. First, use a soft brush and warm water to remove the remaining food particles in the pot. For stubborn stains, use a stainless steel special cleaner, dilute the detergent to water in a ratio of 1:5 and wipe it. Avoid using strong acidic or alkaline detergents to avoid corrosion of the pot body. When cleaning the pot lid, gently wipe the sealing rubber ring to prevent damage to its shape and performance. After cleaning, rinse thoroughly with clean water and wipe the inside and outside surfaces of the pot with a soft cloth. For example, after stewing soup containing tomato sauce, acidic stains may remain in the pot. Timely cleaning with a special detergent can effectively remove the stains and keep the pot clean. This meticulous cleaning and maintenance measures ensure the long-term performance and hygienic safety of the stock pot.

2. Storage and Maintenance

Store the stock pot in a dry, ventilated cabinet to avoid humid environment that causes oxidation of the pot body. When storing, place moisture-proof paper between the pot and the lid to absorb excess moisture. If it is not used for a long time, a thin layer of cooking oil can be applied to the pot to prevent moisture and oxygen in the air from contacting the pot body and causing rust. For example, in kitchens in coastal areas, the air humidity is high and the salt content is high. Storing the soup pot according to the above method can effectively extend its service life and prevent rust. This scientific storage method ensures that the soup pot can remain in good condition during non-use and is ready for use at any time.

3. Avoid collision

During kitchen operation and transportation, be careful to place the soup pot gently to avoid collision with hard objects. If you need to carry it from the stove to the dining table, hold the handles on both sides with both hands to keep the pot stable. If the soup pot accidentally falls or is hit, check whether the pot body is deformed or scratched in time. Once deformation is found, it will affect the uniformity of heating and sealing of the soup pot, and it should be repaired or replaced in time. For example, in a fast-paced restaurant kitchen, if the waiter accidentally hits the soup pot during the delivery process, it may cause dents on the edge of the pot, affecting the cooking effect and appearance. Through careful operation and timely inspection, damage caused by accidental collisions can be avoided and the service life of the soup pot can be extended.

4. Check the sealing rubber ring regularly

Check the status of the sealing rubber ring of the pot lid every 1-2 months. Check whether the rubber ring is aging, deformed, cracked, etc. If fine cracks are found on the surface of the rubber ring, it needs to be replaced in time to ensure the sealing performance of the soup pot. When cleaning the rubber ring, you can use a soft-bristled toothbrush dipped in a small amount of alcohol to gently scrub it to remove surface oil and bacteria. For example, if you cook soup with grease for a long time, the rubber ring is prone to accumulate oil and affect the sealing effect. Regular cleaning and inspection can ensure that the soup pot maintains good sealing and reduce the loss of heat and aroma during cooking. This regular maintenance measure ensures the sealing performance and cooking effect of the soup pot, and improves the reliability and satisfaction of use.

5. Prevent empty burning

When cooking, make sure that there is enough liquid or ingredients in the Heavy Bottom Stainless Steel Stock Pot before heating it to avoid empty burning. Empty burning will cause the temperature of the pot to rise rapidly, resulting in irreversible oxidation and deformation of the stainless steel material, affecting the service life and performance of the soup pot. If the pot is left empty due to negligence, turn off the fire immediately, let the pot cool naturally, and then check the bottom of the pot for damage. For minor discoloration of the pot bottom, wipe it with stainless steel cleaning paste; if there is severe deformation or perforation, the pot needs to be replaced. For example, if the liquid is accidentally boiled dry during soup cooking, the bottom of the pot may appear partially red, bulging, etc. At this time, you need to follow the above steps to avoid further damage. By preventing empty burning, you can effectively protect the pot, extend its service life, and ensure the safety and smoothness of the cooking process.

6. Use cleaning tools gently

When cleaning the pot, choose a soft brush, sponge or wooden cleaning tool, and avoid using abrasive tools such as steel wool and hard scouring pads. Steel wool will scratch the surface of the pot during the cleaning process, destroy the protective layer of stainless steel, and accelerate the oxidation of the pot. For stubborn stains, soak it in hot water for 10-15 minutes, soften the stains, and then gently scrub it with a soft brush. For example, after cooking a soup containing a lot of protein, stubborn protein residue may appear in the pot. Soaking it in hot water and then cleaning it with a soft brush can effectively remove the residue, keep the pot clean, and extend the service life of the soup pot. This gentle cleaning method not only protects the surface of the soup pot, but also ensures the cleaning effect, so that the soup pot always remains in good condition.

Heavy Bottom Stainless Steel Stock Pot FAQ?

What are the benefits of even heat distribution in a stock pot?

Even heat distribution in a stock pot prevents hot spots and ensures that food cooks uniformly. This is particularly important for recipes that require long cooking times, such as soups and stews, as it helps to preserve the flavor and texture of your ingredients.

Can you use a Heavy Bottom Stainless Steel Stock Pot for deep frying?

Yes, a Heavy Bottom Stainless Steel Stock Pot is excellent for deep frying. Its even heat distribution ensures that the oil maintains a consistent temperature, which is crucial for achieving perfectly fried foods. The pot's high sides also help to contain splatters.

How do you clean a Heavy Bottom Stainless Steel Stock Pot?

Cleaning a Heavy Bottom Stainless Steel Stock Pot is straightforward. The smooth surface can be cleaned with warm soapy water and a non-abrasive sponge. For tough stains, a mixture of baking soda and water can be used. Most are also dishwasher-safe for added convenience.

What sizes do Heavy Bottom Stainless Steel Stock Pots come in?

Heavy Bottom Stainless Steel Stock Pots come in various sizes, ranging from 8 quarts to over 20 quarts. The size you choose depends on your cooking needs, with larger pots being ideal for family meals, meal prepping, and entertaining.